Tom Krank named Senior Vice President

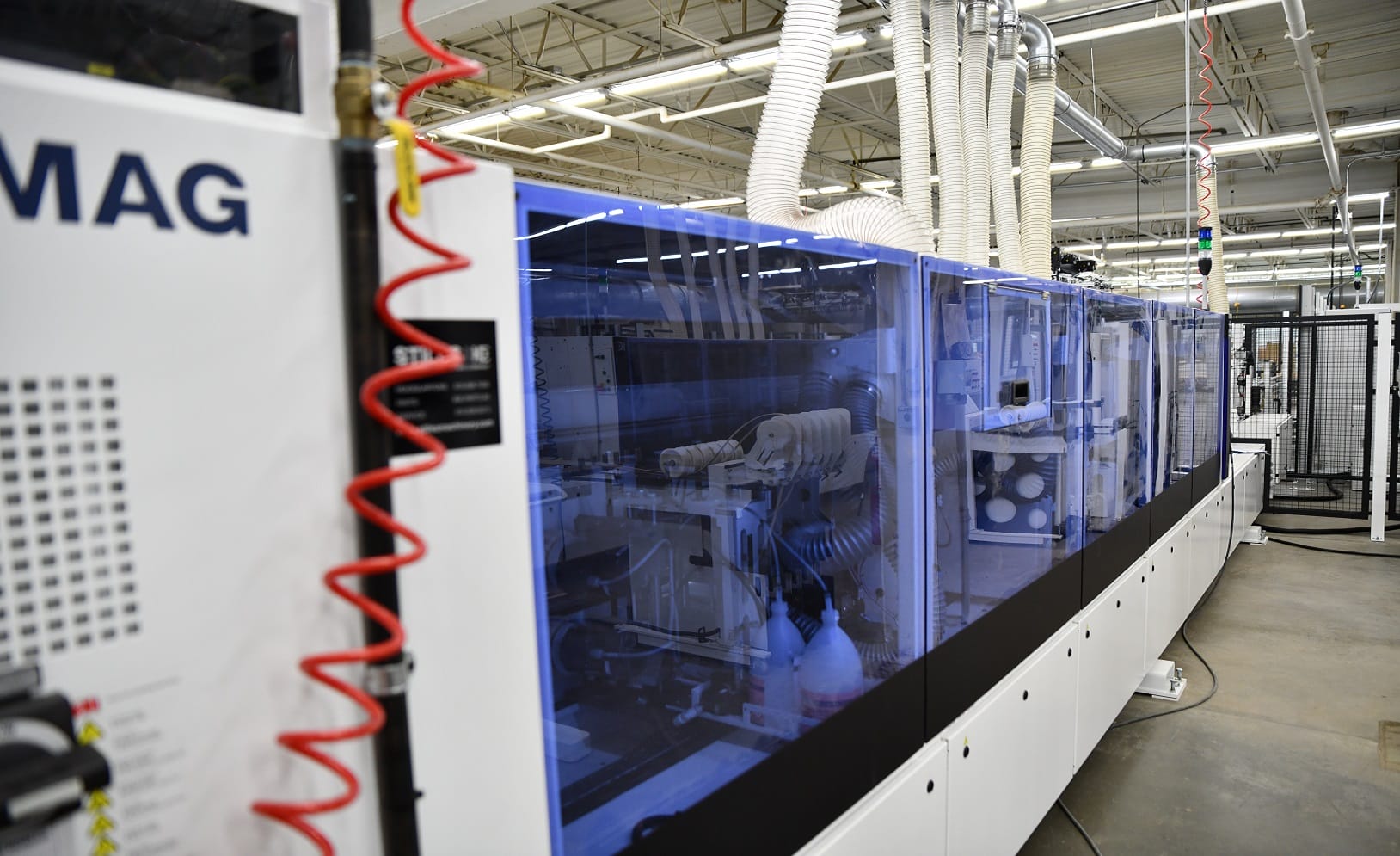

TMI expanded into architectural woodwork, countertops, and direct sales in the late 1980s. At the same time, TMI recognized that the casework market was evolving from a market accepting a manufacturer’s standard product to demanding many more product choices. The number of options grew in quantity and complexity. TMI realized it was in the business of managing information.TMI took advantage of the Y2K challenge and, in 1994, embarked upon a bold software re-write project under the leadership of Tom Krank. Mr. Krank joined TMI in 1979 and, in 2012, was named Senior Vice President.TMI began to convert from a mainframe computer system and stand-alone estimating, drafting, engineering, and materials management software to a client server-based network with highly integrated software. The project was completed and made it possible for TMI to manufacture a highly- customized product line with the ability to download work orders electronically to its significant pieces of factory equipment. The software is known as jSEPP and is a significant competitive advantage for TMI today.